Power Source:AC380V/50Hz

Product Category:Business Card / Tag / RFID Series

| Power Source:AC380V/50Hz |

| Control Method:PLC+Servo transfter+Servo Punching |

| Dimension:2100(L)X1550(W)X1750(H)mm |

| Punching Accuracy:±0.05-0.15mm(Depends on the confirguration) |

| Capacity:600~1200 sheets/hour(Depends on the confirguration) |

| Air Pressure:5-6Kg/cm2 |

| Output method:By conveyor or by serial number. |

| Net Weight:1800KG |

| Gross Weight:2000KG |

| Sheet Size:Customized |

Applying Area:

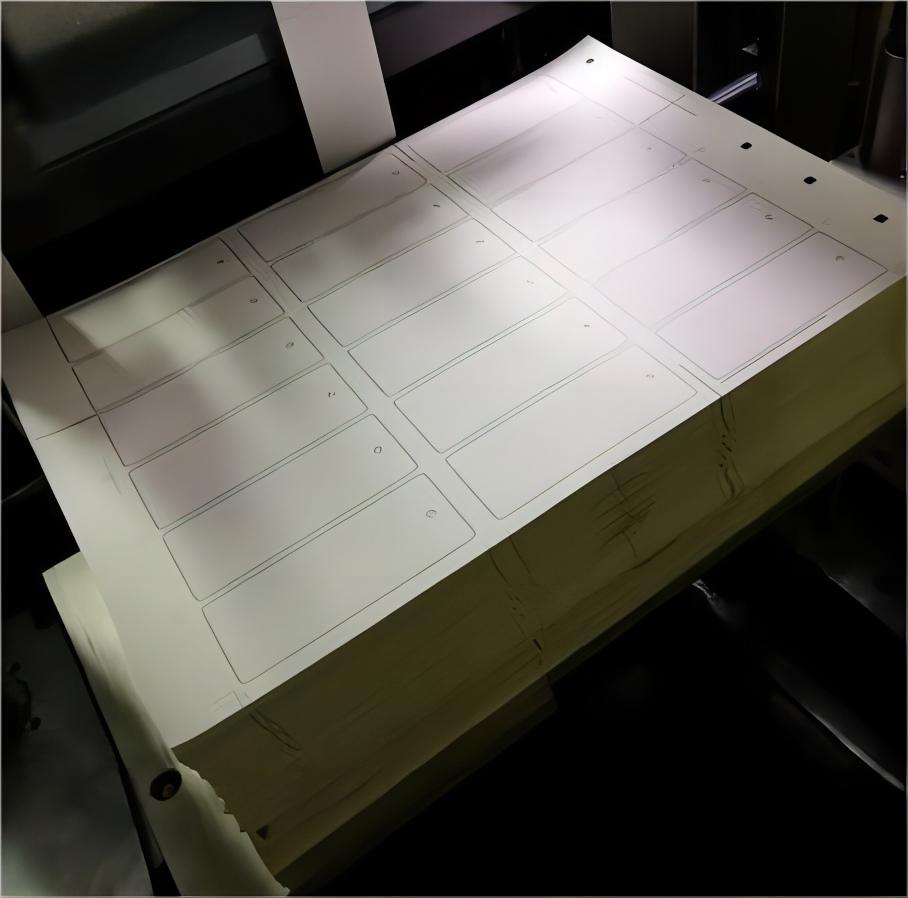

This equipment is used for punching the paper card and PVC cards. Applying 2 high accurate sensors or cameras to do the position, it is very accurate. Applying the servo punching ensures the punching even, stably and environmental. It could work for Poker Card, Clothes Tags,high class cards. The machine is high accurate and effective.

Features:

1.Feeding unit:Auto feeding, applying the lift chain system. The sensors could check the material status.

2.Transfer unit: Applying the high accuracy guide screw and servo system to make the materail running stably and accurately. Applying the high accurate sensors to make the position, make sure the punching accuracy reaches ±0.1mm.

3.Punching unit:Using the servo punching system to make the punching stably and low noise. The punching speed could be adjusted to adapt to different thickness sheets. It is easy to make the punching tool changeover to improve the productivity.

4.Waste Out Unit: applying roll out design to separate the products and waste frame. It could save manpower and improve the productivity.

5.Output Unit: it could make the products sorting by the serial. The machine could be alarm and stop when it occurs abnormal status.

6.Control Unit: applying the PLC or PC to control, it is easy to operate.

7.The outer form and tags could be punched by one pass and no waste. No need manpower to clean the waste.

Copyright © 2022-2023 WINDA co.,LIMITED All rights reserved E-mail:[email protected]